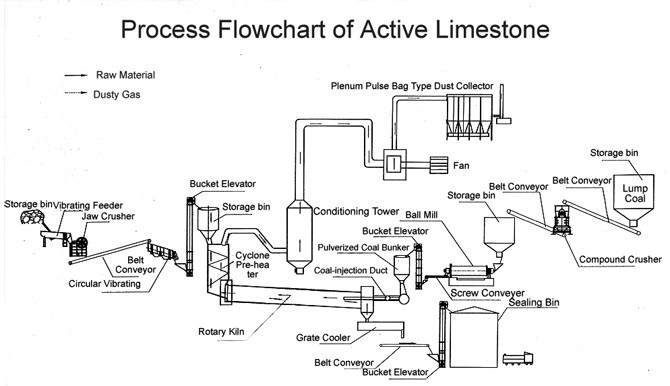

The qualified limestone is store in the material cabin, elevated by the bucket elevator and sent to the material cabin on the top of the pre-heater, and the upper and lower level gage will control the feeding amount and then the filling pipe will evenly distribute the limestone to the rooms of the pre-heater.

The limestone is heated by the 1150℃ smoke inside the kiln to about 900℃, and 30% will decompose, and the limestone is pushed by the hydraulic push rod into rotary kiln where limestone will decompose into CaO and CO2. The decomposed materials go into the cooler where they will be cooled to below 100℃ by the cold air and discharged. The discharged lime will be sent to the final product warehouse through vibrating feeder, chain conveyor, bucket elevator and belt conveyor.

Production Capacity:150-600 t/d

Specification of Rotary Kiln:Φ2.5×40~Φ4.8x68 m

Composing Equipment:

vibrating feeder

chain conveyor