Production capacity: 12–1000 t/h

Diameter of crushing cone: 950–1500 mm

Inlet size: 70–335 mm

Outlet size: 8–50 mm

Weight: 17000–38800 kg

Motor power: 160–400 kw

Material handling: limestone, granite, cobble, dolomite, iron ore, basalt, etc

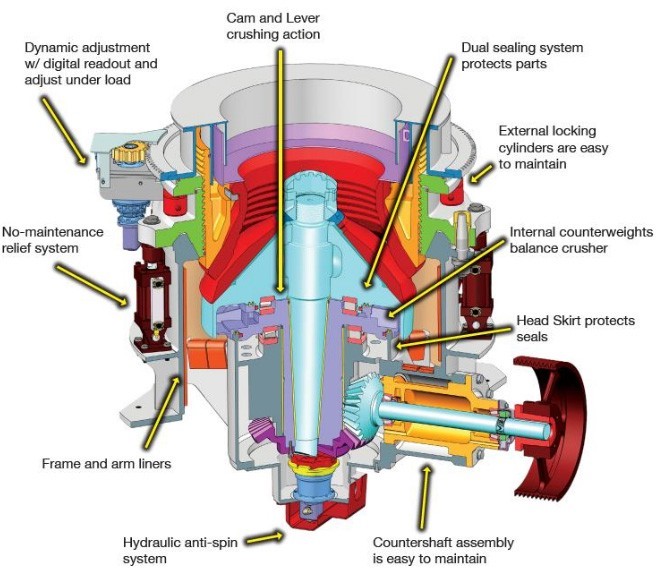

PYG series cone crusher is a new cone crusher researched and development in our company by combing the single-cylinder hydraulic cone crusher and PYG cone crusher and adopting advanced designing concept. Due to the adoption of good crushing frequency and eccentric distance, the content of fine particle materials in the crushed materials is higher, and the content of the materials smaller than the discharging mouth can reach 80%, thus significantly improving the processing ability of the following equipment and reducing the comprehensive energy consumption.

1. The perfect combination of high performance crushing chamber and high crushing frequency of PYG series cone crusher greatly improves the processing ability of this machine, and due to the adoption of lamination crushing principle, the crushed products are in the shape of cube, thus greatly reducing needle-shaped materials.

2. It adopts hydraulic operation, so that the use is convenient and easy to realize automation and its reliability and service life is greatly improved.

3. It is simple in structure, convenient and fast in operation, maintenance and adjustment of the discharging mouth. The examination and repair saves both time and labor, and especially that the lining board is easy to change, thus reducing the stoppage time.

Production capacity: 200 t/h

Processing material: river pebbles, quartz

Benefits: top notch technique support, all-round services

Production capacity: 250 t/h

Processing material: marble

Benefits: complete technique support, all-round services