Processing capacity: 0.2–24 m³/min

Power: 1.5–45 kw

Trough cubage: 0.37–24 m³

Single trough weight: 470–8970 kg

Material handling: quartz, gold, silver, iron, non-ferrous metal, ferrous metal, coal, fluorite, talc, lead, zinc, molybdenum, aluminum, etc

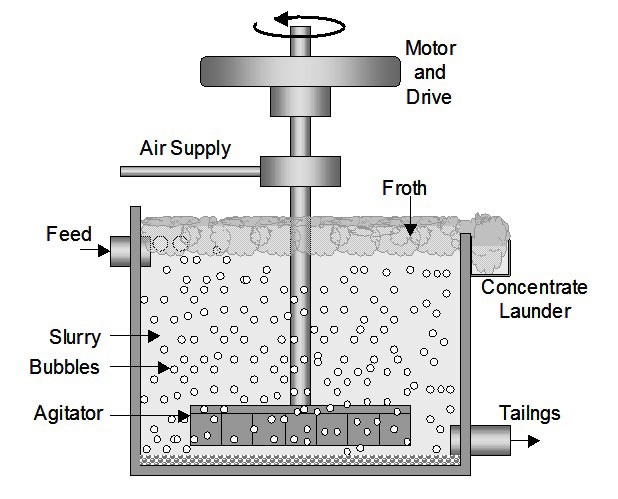

This type of flotation machine is formed by a U-shaped trough, hollow shaft inflation and suspension stator and especially a new type impeller which is a cone impeller whose blades lean backwards just like a centrifugal pump wheel with height ratio rotary speed and it has the advantages of big blending quantity, small pressure, low energy consumption and simple structure.

The structure of flotation machine: this machine is mainly composed of pulp chute, mixing device, air charging system, mineralized froth discharging device and electro motor.

(1) Pulp chute: It has pulp feeding mouth and the gate device used for adjusting the liquid level and it is mainly composed of mainly composed by the chute body which is melt by the steel board and gate melt by the steel board and steel rod.

(2) Mixing device: It is mainly used for mixing the pulp in order to prevent the mineral sand to deposit on the chute, and it is mainly composed by the belt wheel, impeller, vertical shaft and the impeller is made of the anti-abrasion rubber.

(3) Air charging system: It is mainly composed by the inlet air pipe. When the impeller rotates, there will produce negative pressure inside the impeller chamber in order to absorb air through the hollow pump line and disperse the pulp in order to form a froth group.

(4) Mineralized foam discharging device: This device is mainly used for scarping the foam floating on the cell and it is mainly composed by the reducer driven by the electric motor and scrapper driven by the reducer.

| Model | Trough cubage (m³) |

Inside dimensions (L×W×H) (m) |

Air suction amount (m³/㎡·min) |

Power (kw) |

Motor model | Processing capacity (m³/min) |

Single trough weight (kg) |

| BF-0.37 | 0.37 | 0.74×0.74×0.75 | 0.9~1.05 | 1.5 | Y90L-4 | 0.2~0.4 | 470 |

| BF-0.65 | 0.65 | 0.85×0.95×0.9 | 0.9~1.10 | 3.0 | Y132S-6 | 0.3~0.7 | 932 |

| BF-1.2 | 1.2 | 1.05×1.15×1.10 | 1.0~1.10 | 5.5 4.0 |

Y132M2-6 Y132M1-6 |

0.6~1.2 | 1370 |

| BF-2.0 | 2.0 | 1.40×1.45×1.12 | 1.0~1.10 | 7.5 | Y160M-6 | 1.0~2.0 | 1750 |

| BF-2.8 | 2.8 | 1.65×1.65×1.15 | 0.9~1.10 | 11 | Y180L-8 | 1.4~3.0 | 2130 |

| BF-4.0 | 4.0 | 1.9×2.0×1.2 | 0.9~1.10 | 15 | Y200L-8 | 2~4 | 2585 |

| BF-6.0 | 6.0 | 2.2×2.35×1.3 | 0.9~1.10 | 18.5 | Y225S-8 | 3~6 | 3300 |

| BF-8.0 | 8.0 | 2.25×2.85×1.4 | 0.9~1.10 | 22 30 |

Y225M-8 Y250M-8 |

4~8 | 4130 |

| BF-10 | 10 | 2.25×2.85×1.7 | 0.9~1.10 | 22 30 |

Y225M-8 Y250M-8 |

5~10 | 4660 |

| BF-16 | 16 | 2.85×3.8×1.7 | 0.9~1.10 | 37 45 |

Y280S-8 Y280M-8 |

8~16 | 8320 |

| BF-20 | 20 | 2.85×3.8×2.0 | 0.9~1.10 | 37 45 |

Y280S-8 Y280M-8 |

10~20 | 8670 |

| BF-24 | 24 | 3.15×4.15×2.0 | 0.9~1.10 | 45 | Y280M-8 | 12~24 | 8970 |

Production capacity: 150 t/d

Processing material: iron ore, hematite, limonite, manganese ore, ilmenite

Benefits: complete technique support, all-round services

Production capacity: 300 t/d

Processing material: iron ore, copper, zinc, lead, nickel, gold

Benefits: superb technique support, all-round services