Processing ability: 770-2800 t/d

Rotation rate: 2.5~6 r/min

Spiral diameter: 300–3000 mm

Trough length: ≤14300 mm

Dimensions: 3850×490×1140–17091×6640×8680 mm

Material handling: limestone, talc, graphite, barite, mica, kaolin.

Superb technique support, one-stop services

Applicable ranges of spiral classifier: Spiral classifier has four types: high weir single-spiral classifier, high weir double-spiral classifier, immersed type single-spiral classifier and immersed type double-spiral classifier.

Spiral classifier is widely used for separating the sand in the ore beneficiation plant to equip with ball mill to form a closed cycle, for classifying ore sand and fine silt in the gravity separation plant, for the granularity classification of the pulp in the metal ore beneficiation flow and for removing the slime and water in the ore washing process.

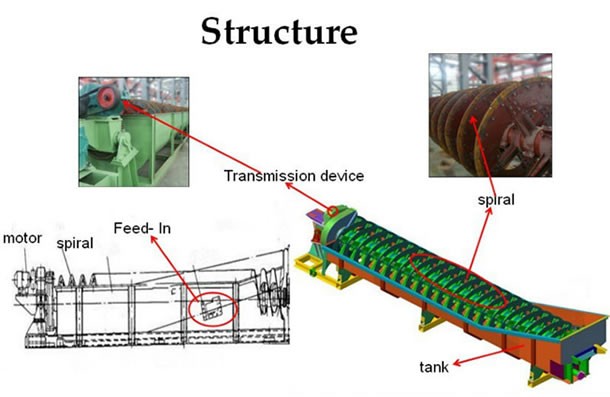

Structure of spiral classifier: Spiral classifier is mainly composed of transmission system, spiral part, chute, lifting part, upper support and ore discharging valve.

Spiral classifier is widely used for separating the sand in the ore beneficiation plant to equip with ball mill to form a closed cycle, for classifying ore sand and fine silt in the gravity separation plant, for the granularity classification of the pulp in the metal ore beneficiation flow and for removing the slime and water in the ore washing process. This classifier has the advantages of simple structure, reliable working condition and convenient operation.

| Model | Spiral Diameter (mm) |

Trough Length (mm) |

Spiral rotate speed (r/min) |

Processing capacity(t/d) |

Motor Power (kw) |

Dimensions (mm≤) |

||||

| Sand -return |

Overflow | For driving |

For lifting |

Length | Width | Height | ||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | ---- | 3850 | 490 | 1140 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 |

| 2FC-30 | 14300 | 23300 | 1410 | ---- | ---- | 17091 | ---- | 8680 | ||